Projects

Whether you are looking for someone to take ownership of a whole Rivercleaner project from start to finish, or just for someone to assist you with certain tasks of your Rivercleaner project, we got you covered and are ready to start.

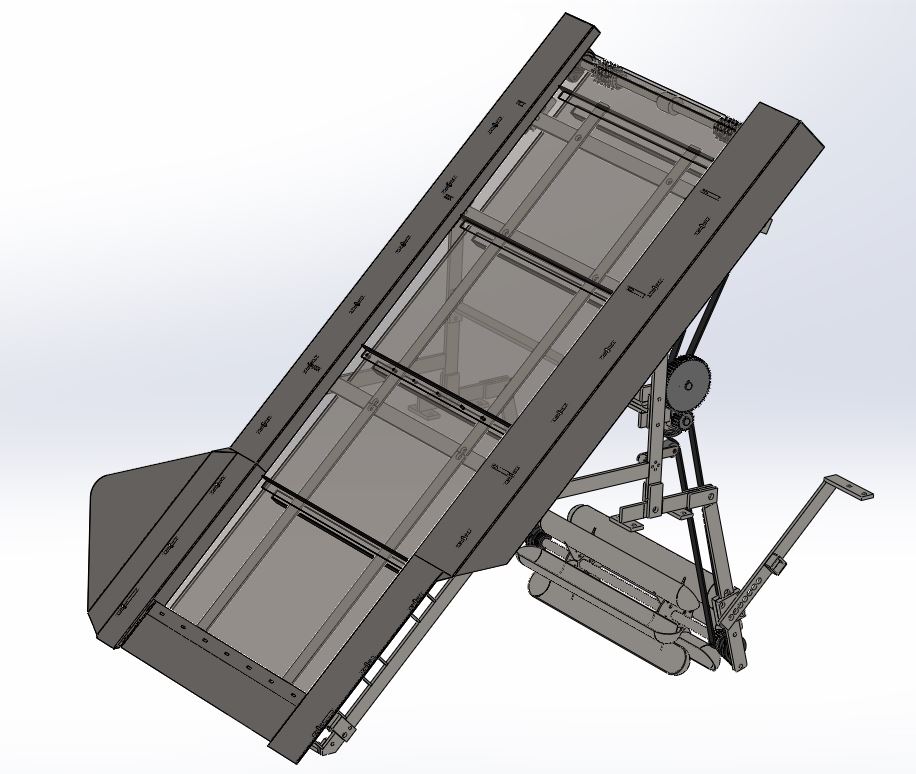

We split each project in steps. Depending on the customers requirements we can skip or add extra steps. Each Rivercleaner is custom made to work most efficiently in its environment. The idea and function of all of our Rivercleaners are the same, but yet every Rivercleaner is a bit different to fulfill its specific requirements as best as possible.

Below is our approach to a project we start from scratch.

Step 1: Liaising with the customer, determining key requirements.

Step 2: Get to know to the operating site and the environment for the future Rivercleaner, measuring the site.

Step 3: Engineering calculations and simulations, e. g. CFD and FEM caluclations. Based on those calculations the Rivercleaner will be designed.

Step 4: Designing process of the Rivercleaner with the latest CAD Software available.

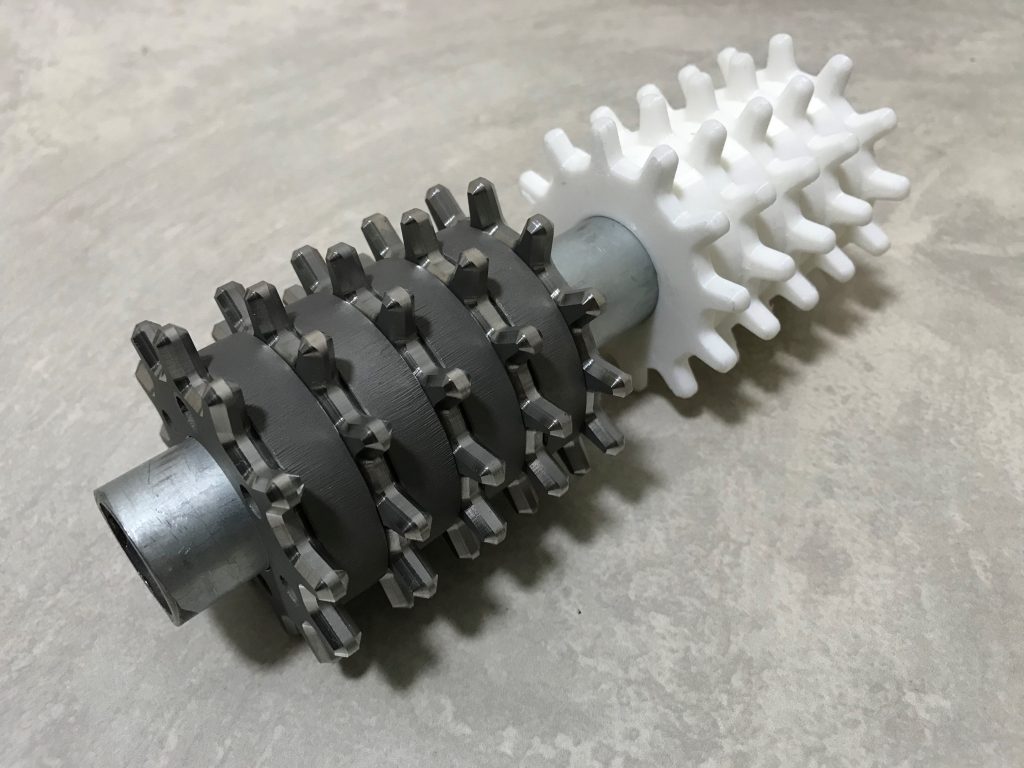

Step 5: Prototyping and 3D printing if certain designs need to be approved first.

Step 6: Manufacturing which includes quick and precise CNC milling, drilling, turning, lasercutting, grinding, welding, surface coating.

Step 7: Test assembly of individual sub assemblies or the whole Rivercleaner on dry land.

Step 8: Assembly of the whole Rivercleaner at its designated place and commissioning.